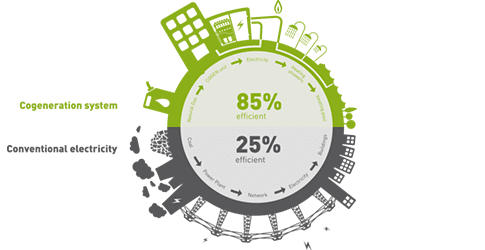

Cogeneration or Combined Heat and Power (CHP) is an extremely efficient technology that converts gas or biogas into electricity and heat in a single process at the point of use.

The Qnergy micro Cogeneration (Micro CHP) unit is designed to provide both heat and power for light commercial or large residential applications.

This innovative product uses an advanced technology to satisfy the energy requirements of the facility and do it quietly, efficiently, and with ultra low emissions. Qnergy can operate on a wide range of fuel types which will provide the best value to the customer.

RANGE – Qnergy 7.5 kWe units that can be “cascaded” together to meet the demands of larger on- site applications. A Qnergy 3.5kWe unit is under development.

Operates with various fuels including natural gas, oil, solar, wood, biomass and biogas

Unique Stirling engine with an extremely efficient combustion process, See below for “how it works”

Operational efficiency of up to 95%, providing the best value to the customer

Thermal efficiency of 83% (LHV)

Zero maintenance required

Great alternative for boiler replacements in any facility where there is a heat requirement.

Multiple systems can be “cascaded” together to meet the demands of larger on- site applications.

Biogas & Natural Gas fired Micro CHP

Using the highly efficient Stirling Cycle thermodynamic process, Qnergy’s free-piston Stirling engine (FPSE) can create electricity from virtually any heat source. The heat input creates a temperature differential across the engine causing the helium inside the sealed chamber to expand and contract, which in turn drives the reciprocating motion of the piston. The FPSE directly converts the reciprocating motion of the piston into electrical power via linear alternator.

The Qnergy engine has fewer moving parts than traditional kinematic Stirling engines, and no direct-contact points that cause wear and require lubrication. Thus, the Qnergy engine is truly a maintenance free technology that offers long-life performance. These two key features make it an ideal power source for combined heat and power applications.

Simons Green Energy are exclusive distributors of Qnergy Micro CHP in Australia

YANMAR Micro Cogeneration units use Natural Gas or Biogas to produce electricity on site and transform waste heat into space heating, domestic hot water or process heat depending on each site’s power and heating requirements.

RANGE – The range includes 5kW, 10kW and 25kW units and have efficiencies of up to 85%, as compared to the 25% efficiency of coal-fired grid-supplied electricity.

Plug and play –Compact, stand alone “plug and play” units, with integrated dump radiator, ventilation and inverter.

Outdoor or indoor installation

Daisy Chained – The Yanmar units can be “daisy-chained” for increased output and will load follow to suit any site’s instantaneous electricity demand.

Flexible installation – Compact units for outdoor or indoor installation with a low operational noise

Monitoring – All units have remote monitoring and diagnostics capabilities

Reliable operation – 10,000 hour maintenance interval

Applications – Perfect for aged care facilities, aquatic centres, hotels and pubs

Simons Green Energy are exclusive distributors of Yanmar Micro CHP in Australia.

Talk to one of our engineers to discuss your requirements.

Europe’s largest packaged Cogeneration supplier with 2,500 units operating in 11 countries across the globe.

ENER-G’s experience in the Cogeneration market dates back to 1984 when they began designing, manufacturing, installing and maintaining Cogeneration systems in the UK. They are now firmly positioned as Europe’s leading supplier of Cogeneration systems.

Exclusive distributors of ENER-G’s complete range of Natural Gas and Biogas powered CHP units in Australia. Simons Green Energy has won the ‘Fastest Growing Cogen Partner 2013 ‘Award for its leading role in developing the Australian Cogeneration market. Click here

RANGE- Sizes range from 35kW to 2,140kW for Natural gas applications and 81kWe to 1,558kWe for Biogas application

Packaging options include Acoustic Enclosures, Containerised Systems, Skid Mounted Systems and bespoke custom designed units.

Engines available – MAN, MTU, Perkins, MWM and ENERG reciprocating engines.

Patented Monitoring System is an integral part of the CHP unit. The on-board computer assures efficient operation of the CHP and provides live monitoring with full historic data retrieval.

SGE-VISION remotely monitors the units assuring maximum operating up time. Read more

Trigeneration – with the addition of an absorption chiller, the waste heat from the Cogeneration System can be converted into chilled water for air conditioning.

Simons Green Energy can design, install, commission and provide lifetime care of all ENER-G units, assuring the highest system performance and customer satisfaction.

Talk to one of our engineers to discuss your requirements.

Cogeneration projects are traditionally different. One size does NOT fit all.

Simons Green Energy will partner with you to find the CORRECT Cogeneration Solution for your business. Our exclusive partnerships with international suppliers allow us to provide a wide range of engine sizes to suit your specific needs.