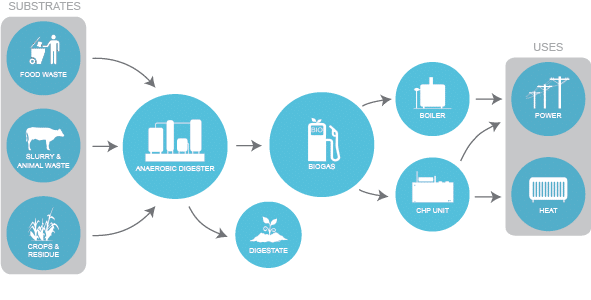

Disposal and treatment of biological waste represents a major challenge for the agriculture, food processing and manufacturing industry. We provide complete Biogas energy solutions that convert organic waste into both electricity and heat on site.

Turning waste to energy can be a complex process so it is important that you choose the right supplier to partner with.

Simons Green Energy can deliver the entire waste to energy solution from initial feasibility to system design and installation, maintenance and financing. We work with our clients to find the best Biogas solution according to the site’s waste stream and energy consumption requirements.

Whether your need be for electricity, hot water, steam, or purely methane capture, Simons Green Energy has the knowledge, experience, skills and products to customise a solution that best fits your needs.

WHAT ARE THE BENEFITS TO MY BUSINESS?

The capture of Biogas from landfill, farming effluent streams, or other organic waste provides an immediate offset of the carbon emissions produced from the natural decomposition of organic material. Our waste to energy solution will convert that Biogas into electricity and heat, saving your business money.

The output yield of Biogas depends on the type of feedstock used by the system. Different feedstock will yield different levels of Biogas energy potential. Some waste, such as food scraps and animal fats have a high Biogas yield. Often, these are mixed and co-digested with lower yield feedstocks such as animal slurries to maximise the benefit and return from the system.

Turning waste to energy can be a complex process so it is important that you choose the right supplier to partner with.

Converting waste into useful energy provides businesses with the opportunity to reduce overall operating costs and cut carbon emissions. Simons Green Energy helps businesses across industries to identify such opportunities and designs the best Biogas solution according to each site’s requirements.

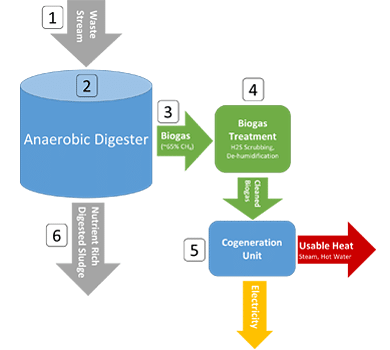

1- Waste stream (feedstock) is input to the digester.

2- Through a microbial process, organic material is broken down into Biogas comprising of 60-70% Methane (CH4), the combustible portion of the gas.

3- Biogas produced in the anaerobic digester or covered lagoon is extracted and compressed to working pressure.

4- If specified by the end use, Biogas is then scrubbed of H2S, which can cause increased wear on mechanical components, and de-humidified.

5- In the case of a Cogeneration system, Biogas is combusted to produce usable electricity and heat.

6- Waste sludge from the digester is high in nutrient content, and can be used as fertiliser, further increasing the value from the entire system and closing the loop on the waste stream.

For more information about how you can generate or use Biogas available in your site please contact our engineering team.

Simons Green Energy can deliver the entire waste to energy solution to your business. We integrate different technologies and system components according to your site’s requirements.

Simons Green Energy works with industry partners to design, manufacture and install Anaerobic Digester systems (which may include covered lagoons and mixed engineered systems). We manage all aspects of the installation from civil works through to mechanical works and commissioning.

For farm and landfill application, with existing sewage ponds or landfill sites, over tight covering with a specially engineered robust and flexible membrane is a relatively low-cost way of capturing Biogas. Capturing and flaring these methane emissions provides an immediate 20- fold reduction in carbon footprint! Using the energy value of the methane to offset electricity and natural gas provides even greater financial and environmental benefits. More complex digester solutions may be required to improve the yield and provide additional control over Biogas production. Simons Green Energy can engineer these to suit site needs.

We offer a range of boilers configured to operate on Biogas or on a combination of natural gas, propane and Biogas. Simons Boilers has over 80 years’ experience in boiler manufacture and sales and we can design and install a Biogas boiler to suit any size and output requirement.

Our Biogas Cogeneration Systems range from micro-scale CHP units of 7.5 kW through to large-scale systems of over 2 MW of electrical capacity. The ideal configuration is site-specific and the best option for your business will be determined following a detailed energy, process and economic analysis.

ENGINE BASED – CHP

Simons Green Energy is the exclusive Australian distributors of YANMAR Micro-Cogeneration and ENER-G Cogeneration units. These reciprocating enginebased CHP units provide a proven and simple method for producing heat and power from Biogas at a low cost.

ENER-G CHP 81 kWe to 1,558 kWe packaged units can be configured with MAN, ENER-G, MTU, Perkins, Caterpillar Biogas engines.

YANMAR 25 kW Micro CHP are compact, stand alone “plug and play” units, with integrated dump radiator, ventilation and built-in inverter. For outdoor or indoor installation, these units can be “daisy-chained” for increased output and will load follow to suit any site’s instantaneous electricity demand.

STIRLING ENGINE BASED – CHP

Qnergy’s 7.5 kW Stirling Engine based CHP

Qnergy’s 7.5 kW Stirling Engine based CHP units are manufactured in the USA. Unlike conventional reciprocating engines, Stirling engines are an external combustion design. This means they can operate with a very wide variety of fuels including Biogas, natural gas and wood waste. Stirling engines have the advantage of a high tolerance to moisture and H2S content. The Qnergy system efficiently generates electricity while generating a substantial amount of hot water.

MICROTURBINE – CHP

Simons Green Energy can supply micro turbines from leading international manufacturers. They have a proven track record for reliability in Biogas applications, low maintenance costs and good thermal efficiency.

Simons Green Energy can supply all supporting equipment necessary for a complete Biogas system sourced from reputable local and international suppliers. This equipment includes:

Our turnkey Biogas energy solutions provide a cost-effective alternative to manage and convert organic waste into electricity and heat, reducing production costs while cutting carbon footprints.