The Waste Heat Steam Generator recovers heat from a hot gas or water stream and produces steam that can be used in industrial and manufacturing processes or used to drive a steam turbine to improve efficiency (combined cycle).

The waste heat steam generator (WHSG) utilises otherwise wasted energy from 450 degree exhaust gases from a cogeneration unit to produce dry steam. It can supplement or replace standard gas-fired steam boilers, and improves overall system efficiency, reduces operating costs, and lowers your carbon footprint.

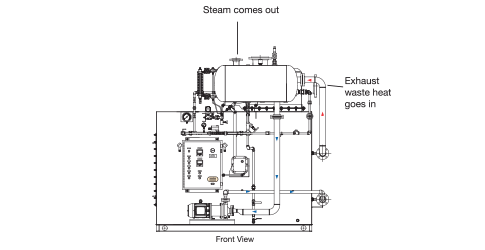

From a holding tank, water is circulated through the hot exhaust gases via a heat exchanger, producing super-heated steam. A control system continuously monitors steam and water levels in the tank to ensure optimal availability, and will vary the exhaust gas flow to cater for fluctuating loads.

Waste Heat Steam Generators have output capabilities of 20 to 300 boiler hp and operating steam pressures from 3 to 450 psig.

The system is made up of three basic sections:

• Finned tube heat transfer section

• Steam flash circulating drum assembly

• Modulating full port exhaust bypass system for safe automatic steam control

Its self-contained package design reduces engineering, installation, and maintenance costs as well as floor space requirements.

Completely self-contained package design reduces engineering, installation, and maintenance costs.

Many shapes and sizes are available to fit limited space and maintain performance requirements

Produces more than 99% dry steam

Provides 100% turn down capability.

5–10 minutes from startup to full output.

Integrated exhaust modulating bypass for safe automatic steam control.

Explosion-proof heat transfer exchanger.

No thermal expansion concerns with cold boiler feed water.

Waste Heat Steam Generator

It produces greater than 99% dry steam and provides 100% turndown capability, with 5–10 minutes from start-up to full output.