BACKGROUND

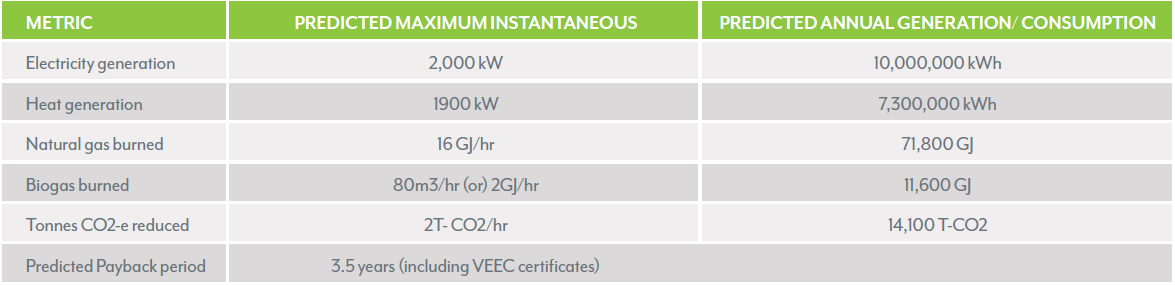

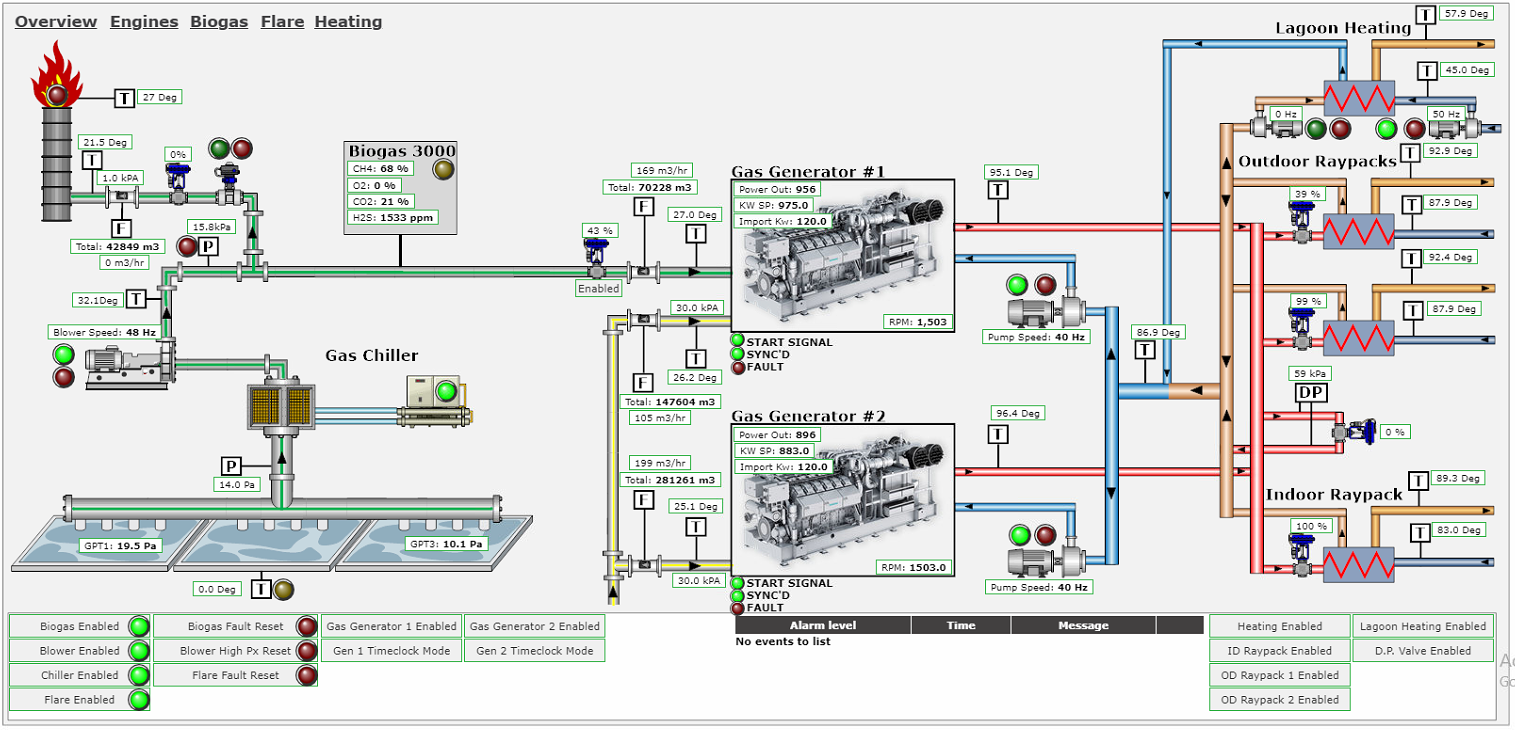

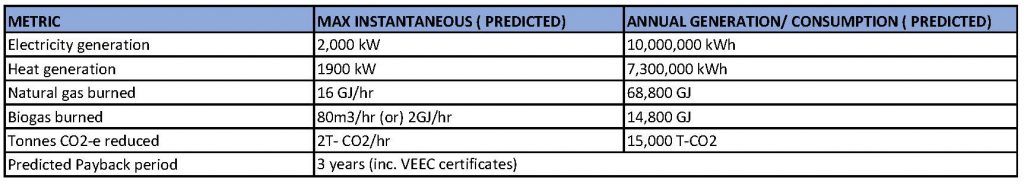

Simons Green Energy were engaged to provide an in-depth feasibility study to assess the suitability of Greenham installing a mixed fuel cogeneration System on their site in Tongala. The system needed to make good financial sense as well as offer environmental benefits.

Simons were subsequently appointed the project and provided the client an end-to-end solution from initial design to project completion.

Simons provided:

- Design and specifications

- Project Management including quoting and ordering

- Regulatory Approvals – Liaising and approvals which is a time consuming and difficult task

- Installation on site – project managing any external contractors on site

- Commissioning and trouble shooting

- Monitoring of equipment

- Preventative maintenance and breakdowns

Simons partnered with Siemens to provide the two cogeneration units that are installed on site. The cogeneration units operate 24 hrs/day 5 days a week and the installed cogeneration and biogas system is fully automated with remote monitoring by a customed designed PLC control system. The controls system monitors all the conditions of the site including both cogeneration units, the pumps, the pressures and temperatures of all relevant systems including biogas CAL pressures and flare.

The system utilises two SGE-42HM 1000kW Siemens cogeneration units set to deliver power and heat to the abattoir. SGE covered three of the existing anaerobic lagoons to capture the methane that was naturally being generated in the ponds. The treated methane as well at natural gas power the engines creating electricity and heat.

Simons Green Energy had several key missions

- Provide the customer with a positive financial outcome

- Reduce the operating carbon emissions for Greenham Tongala

- Ensure to engage and provide work to as many local trades as possible in order to contribute to the local economy.